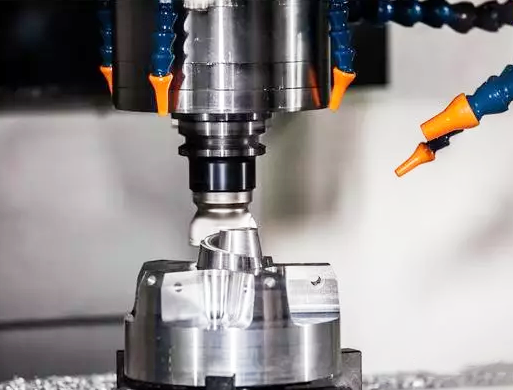

Nts'etsopele ea mahlale a tsoetseng pele joalo ka ho sebetsa ka nepo China ke ea bohlokoa haholo mochining le tlhahisong ea China.Mabapi le moralo, moralo o thusoang ke komporo (CAD) o tumme.Mabapi le ts'ebeliso, litheknoloji tse fapaneng tse phahameng le tse ncha li tsoetse pele ka potlako mme li fihletse litholoana tse makatsang.Mabapi le tsamaiso, lipatlisiso le tloaelo ea mokhoa o mocha oa tlhahiso o na le litšobotsi tsa oona, tse khothalelitseng tsoelo-pele ea theknoloji le tsamaiso ea morao-rao ea indasteri ea tlhahiso ea Chaena.Theknoloji e ntlafalitsoe haholo ho machining a nepahetseng, 'me mochini o nepahetseng o tla etsa hore mokhoa oa ho etsa o atlehe haholoanyane.Ka tsela ena, tlhahiso le nts'etsopele ea rona li tla kena "mokhoeng o motle oa potoloho".

Lilemong tse mashome a mabeli tse fetileng, indasteri ea tlhahiso ea mechini e ntse e tsoela pele molemong oa ho sebetsa ka nepo le ho sebetsa ka mokhoa o nepahetseng haholo ka lebelo la nts'etsopele.Ts'ebetsong ea nts'etsopele ea nako e tlang, ho sebetsa ka mokhoa o nepahetseng le ho sebetsa ka mokhoa o hlakileng haholoanyane e tla fetoha theknoloji ea mantlha ea ho hapa tlholisanong ea machabeng le tlholisanong ea 'maraka.Nts'etsopele ea indasteri ea sejoale-joale ea tlhahiso e ikemiselitse ho ntlafatsa ho nepahala ha mochini.Lebaka le ka sehloohong ke ho ntlafatsa tshebetso le boleng ba lihlahisoa;Ntlafatsa botsitso ba boleng ba eona le ts'epahalo ea ts'ebetso, ho khothaletsa miniaturization ea sehlahisoa, ts'ebetso e matla, ho feto-fetoha ha likarolo tse ntle, kopano e phahameng ea lihlahisoa le tlhahiso ea tlhahiso, le ho khothaletsa tlhahiso le boiketsetso ba kopano.Ka nts'etsopele ea indasteri ea tlhahiso, machining a nepahetseng joale a ntse a tsoela pele ho tsoa lits'ebetsong tsa micron le submicron.Nakong e tlang, ho nepahala ha machining a tloaelehileng, machining a nepahetseng le machining a ultra precision a ka fihla ho 1um, 0.01um le 0.001um ka ho latellana.Ho feta moo, machining a nepahetseng a ntse a lebile ho nepahala ha mochini oa athomo.Ka ntlafatso e tsoelang pele ea ho nepahala ha moeli, ha e etse feela maemo a nts'etsopele le tsoelo-pele ea saense le thekenoloji, empa hape e fana ka mokhoa o motle oa thepa bakeng sa mochine o batang oa mechine.

Theknoloji ea tlhahiso ea mechine e tsoetse pele ka potlako ho tloha ho ntlafatsa ho nepahala le tlhahiso ka nako e le 'ngoe.Mabapi le ho ntlafatsa tlhahiso, ho ntlafatsa boemo ba automation ke tataiso ea nts'etsopele ea linaha tsohle.Lilemong tsa morao tjena, ho tloha ho CNC ho ea ho CIMS e tsoetse pele ka potlako 'me e sebelisitsoe ka mefuta e itseng.Mabapi le ho ntlafatsa ho nepahala, ho tloha ho machining a nepahetseng ho isa ho machining a ultra precision, ena hape ke tataiso ea nts'etsopele ea linaha tse kholo tse tsoetseng pele lefats'eng.Ho khaola ho 'nile ha sebelisoa haholo libakeng tse ngata, hobane litlhoko tsa tlhahiso ea mechine bakeng sa tlhahiso li fokotsehile,' me litlhoko tsa boholo le sebōpeho li eketsehile butle-butle.Precision machining e na le mokhoa o mocha oa nts'etsopele.Ho sebelisa lathes ho hloka mekhoa e fapaneng ea ho fetola.Leha ho le joalo, ho sila, ho seha li-gear, ho sila le lits'ebetso tse ling ho ka etsoa ka lathe e le 'ngoe.Mokhoa oa tsoelo-pele oa ho kopanya ts'ebetso o bohlokoa haholo.

Nako ea poso: Dec-14-2021